At Airteq we understand fume extraction. We also understand there is no “one solution” to cover clients needs. With our combining knowledge in the Dust and Fume Extraction industry and experience in fabrication and welding processes we are able to bring to the UK our Airteq range of weld and fume extraction products. We believe these products provide the best combination of quality, durability and value for money available in the UK. Whether you need a single mobile extraction unit or a complete turnkey fume extraction system Airteq can provide the answer.

Fume Extraction Arms

The self-supporting fume extraction arms are the most versatile, durable and economical method of at-source air pollution capture. Smooth steel tubes, flexible hoses and external joints make Oskar arms easy to work with and keep it in position for required time. Oskar fume arms are available in diameters of 75, 100, 125, 160 and 200 mm. Oskar fume arm unique design has become an industrial standard in air pollution control business.

Flexible Hose Arm

The 160 flexible hose extraction arm is designed for local air pollution control at less demanding applications. This product is made of flexible hose and internal support mechanism with counter support spring and friction disc joints. Econ 160 hose extraction arm is cost effective alternative to tube arms used for frequent air pollution source capture in workshop environment. There are two models of this product. Hanging model can be used on wall or overhead. Standing models are designed to work right on work bench, table surface or on mobile filter units.

Telescopic Fume Arm Tele 160

Tele 160 telescopic fume extraction arm has been designed for work in small, confined spaces especially with low ceilings. Tele 160 extraction arm is a unique construction which main principle is not to keep any internal mechanisms inside. The only device left inside is an air flow damper (no damper model available). Oskar telescoping arm is made of outside cast aluminium joints and two tubes which can move and rotate within each other. This product does not require any counter weight to work. Smooth tube design allows the lowest pressure drop as well as low noise levels. Construction of Tele 160 (like all other Oskar tube arms) means remarkable long product life time and simple maintenance. All adjustments on the outside allow for telescoping arm tension corrections without stopping air exhaust, contact with polluted air stream or fume arm interior.

Fume Extraction Stainless Steel Arms

Stainless fume extraction arms are the most advanced, versatile, and durable method of capturing air pollution at its source. the arm duct (from hood to mounting swivel) is made of stainless steel. Depending on application demand the stainless arm can be configured with stainless joints (models 75 and 100), raw or anodized aluminium elements, food grade, high temperature resistant or electrically conductive elastic hoses. Large choice of components combinations makes the stainless arm one of the most versatile products in its group

Extension Boom

The swinging extension booms are designed to increase the reach of self-supporting arms or other exhaust products like hose reels and flexible hose drops. The extension boom helps to reach areas distant from a wall or mounting point. They can also be used to support items such as feeders or underslung hoses or cables. Top and bottom outlet of boom wall mounting bracket is ready to accept a fan or duct connection. The extension beams are manufactured of heavy gauge square steel tube welded to a heavy-duty hinge. As a standard, all units are supplied with an inlet bracket to mount the fume arms. Double pivot type extension booms are divided by a centre hinge which allows the user to reach back under the extension boom or just simply to reach around the corner. There are no internal mechanisms within the boom duct which allows the lowest pressure drop as well as low noise level. All adjustments mechanisms are designed on the outside of the boom. The extension booms are heavy-duty products of remarkable reliability and operational lifetime.

Extraction Fan

The fans have been designed to work with various Products. source capture devices as well as with clean or polluted air extraction installations. Aluminium impellers enclosed in steel powder coated housings ensure high airflow efficiency and spark-proof design. The fan units are used to exhaust non-explosive and chemically non-aggressive gases of temperatures up to 40oC. the fans are perfect with units are radial impeller backward inclined blade fume extraction fans designed to work with Oskar point extraction products such as fume arms, extension booms, sliding rails, car exhaust hose reels or hose drops.

Boxair Mobile Cassette Filter

Mobile casette filter unit Boxair Basic is designed for extraction and filtration of welding fumes and dust. Its main features are compact dimensions, solid steel construction and high maneuverability. Boxair Basic mobile filter unit consists of a G2 class filtration mat, secondary M5 class filter cartridge and a disposable F9 class main compact filter. The recommended equipment for the Boxair Basic filter unit is the Econ fume extraction arm with a range of 2 meters.

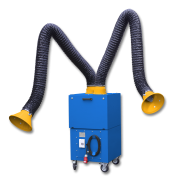

Boxair M2

Boxair M2 is a mobile filter unit designed for designed for extraction and filtration of of fumes and dust created mainly during welding processes. Boxair M2 allows at-source air pollution capture thanks to use of fume extraction arm Econ or Oskar 160 series. Filter set consist of a metal mesh pre-filter and F9 class disposable main compact filter.

Crawlair Mobile Cartridge Filter

Crawlair Mobile cartridge filter is designed to exhaust and filter dry impurities like fume or dust at various industrial processes (especially at welding, grinding, polishing, cutting of metals or plastics). Crawlair M is equipped with metal mesh spark trap pre-filter and two high efficiency (99% at 1μm) polyester filter cartridges which are washed with built-in manual (optional timer controlled) compressed air cartridge cleaning system (10 litre tank built-in). Thanks to large rear wheels, two swivel casters with brakes and pull handle moving with Crawlair around work area is easy and simple. 160 fume arm models or Econ 160 hose arms are recommended for at-source fume capture. Additional front air inlet allows connections to other production equipment. As an option Crawlair unit can be equipped with automatic start/stop function and LED light for fume arms.

Roll Out Mobile Cartridge Filter

Rollout Mobile Cartridge Filter is designed to exhaust and filter dry air borne pollutants especially at welding, grinding, polishing, cutting of metals and plastics. Rollout features 3 stage filtration with metal mesh prefilter (spark-trap), main cartridge filter and outlet activated carbon filter. Standard manual (timer in option) regeneration system is can be used to clean main cartridge during filter operation. Rollout is advised for most demanding applications where the constant exhaust and filter operation is required. We reco mmend Oskar 160 2 or 3 m models as a at source capture devices with Rollout filters. Optional configurations feature LED lights built-in arm hood as well as photosensor triggered automatic operation.

Crawlair Overhead Cartridge Filter

Crawlair Overhead cartridge filter is designed for dry air pollution control like fume or dust at various industrial processes (especially at welding, grinding, polishing, cutting of metals or plastics). Crawlair Overhead is equipped with metal mesh spark trap filter and two high efficiency (99% at 1μm) polyester filter cartridges which are washed with built-in manual (optional timer controlled) compressed air cartridge cleaning system (10 litre tank built-in). Oskar hanging fume arm models 1620, 1630 or Econ hose arms H1620, H1630 are recommended choice for Crawlair Overhead. As an option Crawlair can be equipped with automatic start/stop function and LED light-kit for fume arm.

Giant 2 Mobile CArtridge Filter

Filter Giant 2 Mobile Cartridge Filter is designed to exhaust and filter dry air borne pollutants especially at welding, grinding, polishing, cutting of metals and plastics. Giant 2 features 3 stage filtration with metal mesh prefilter (spark-trap), main cartridge filter and outlet activated carbon filter. Standard manual (timer in option) regeneration system is can be used to clean main cartridge during filter operation. Giant 2 is advised for most demanding applications where the constant exhaust and filter operation is required. We recommend 2 or 3 m reach arm standing models as at source capture devices for Giant filters. Optional configurations feature LED lights built-in arm hood as well as photosensor triggered automatic operation.

S-1000 Welding Table with Extraction

S-1000 welding table is a work station equipped with air pollution capture and exhaust devices which appear with workshop processes (especially during welding). S-1000 table frame, made of heavy-duty square profiles, features built-in downdraft exhaust, fume arm connection inlet and ZWR-03 aluminium radial impeller fan unit. Downdraft exhaust and fume arm individual dampers allow airflow adjustments as fan unit transports air pollution to the outside of premises (discharge installation must be connected). The surface of the S-1000 welding table has been coated with conductive corrosion protection and grounding table can be connected on the left or right side of the table frame. S-1000 welding table complete sets are offered with revolving table for more productive work on smaller elements.

SF-1000 Welding Table

SF-1000 welding table is a work station equipped with capture, exhaust and filtration system which protects from air pollution appearing with workshop processes (especially during welding). SF-1000 table frame, made of heavy-duty square profiles, features built-in downdraft exhaust, fume arm connection inlet and ZWR-03 aluminium radial impeller fan unit. Downdraft exhaust and fume arm individual dampers allow airflow adjustments. Capture air pollution is transported to Crawlair filter unit which purifies air through preliminary filter and cartridge filter module. Crawlair filter unit feature cartridge regeneration system which can be run manually or with optional timer. The surface of the SF-1000 welding table has been coated with conductive corrosion protection and grounding cable can be connected to the left or right side of the table frame. SF-1000 welding table complete sets are offered with revolving table for more productive work on smaller elements.

Hose Reel

lBasic Klimaroll exhaust hose reels application is extraction of car fumes in garages, car repair and maintenance shops or car showrooms. Thanks to Kimaroll exhaust hose reel you will maintain order in the workplace and, with easy to operate flexible hose, you will be able to locate and exhaust air pollution at source. When the exhaust hose is no longer needed simply wind it back on the hose reel which you can mount on the wall or under the ceiling. Spring recoil Klimaroll SP allow for automatic hose return of the hose and desired hose length can be chosen with use of built-in ratchet mechanism. Klimaroll E models, equipped with an electric motor, are easy to work with use of up/down on-wall switch (models EP) or remote controller (models ER). Standard hose reels are equipped with 102, 127, 157 diameter and 10M length crash-proof flexible hoses which are up to 150°C.

Sliding Suction Rail

Sliding suction rail has been designed to allow transport of fume extraction equipment (fume arms or hose drops) between air pollution sources. SSR suction rail is used with manual and automatic welding, machining as well as automotive exhausts in car repair facilities. Thanks to sliding suction rail one or two fume extraction sets can be moved between a number of air pollution emissions. Sliding suction rail main construction element is standard 4-meter long segment made of aluminium profiles, reinforcements and exhaust trolley (standard inlet dia. 160 mm) travelling between self-sealing rubber flap. Suction rail segments can be connected together to form long movable extraction systems. Trolley ready to use with the fume extraction arm or hose drop (set of elastic hose, nozzle and balancer).

Modular Cartridge Filter System FPM

Standard FPM system has been designed for a collection of non-explosive and chemically non-aggressive dry dust arising at many industrial processes. Thanks to highly efficient separation degree clean air can be returned (depending on the type of process) back to production premises.

Filter unit construction features filter base with dust collection drawers, filter cartridge chamber and compressed air cartridge cleaning chamber. The exhaust fan can be delivered mounted on top (with or with-in noise-proof enclosure) or mounted free standing on the side of the filter unit.

Modular FPM construction allows custom configurations tailored to application requirements as well as to conditions of installation site or way of delivery. Modular filter parts are powder coated and galvanized for corrosion protection (antistatic coating available as separate option). FPM configurations are complemented with cartridge filters, which proper selection provides total filtration surface adequate to the type of air pollutant as well as to airflow capacity.

Though FPM system has been primarily designed for welding smoke, cutting, grinding of metals and plastics, it can be used with many other industrial dry dust applications